Best Broaching Ever

Best Broaching Ever

Broaching evolves with rotary, single-point and CNC-driven tools, plus cleaner electromechanical machines—delivering faster cycles, higher accuracy and lower costs.

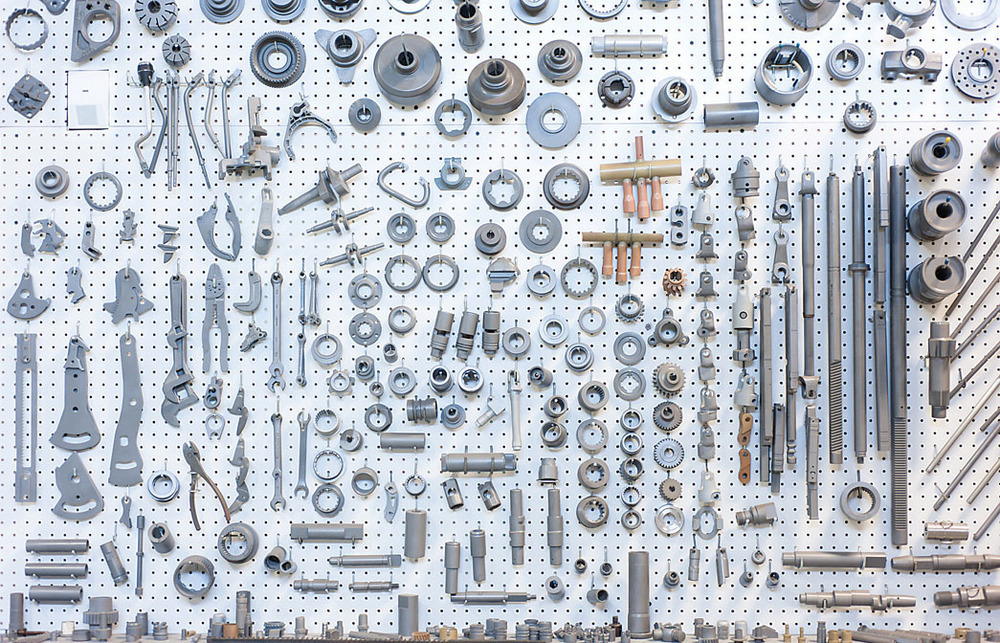

Broaching can produce a wide variety of parts, a small sample of which is shown here. BMS

The name dates back to the 1800s, but broaching has taken big leaps forward since its early days. Though still used to produce challenging shapes, modern versions of the process feature machines and tools that offer significant advancements in speed, accuracy and part quality, while also lowering manufacturing costs. As an added bonus, some of the latest systems operate in a way that's friendlier to the plant and environment than older broaching technology.

"When people talk about broaching in general, oftentimes they're referring to pull-style broaching, where you have a 3'-long broach with graduated teeth that are pulled through the part," said Kris Renner, director of operations at Slater Tools Inc., a broach tool manufacturer in Clinton Township, Michigan. "That is the conventional, old school method of broaching, and there are certain applications that are appropriate for that method to this day."

A more advanced process, however, is rotary broaching, which can be done on a lathe or mill. The broach is held by a toolholder with a live spindle angled at about 1° relative to the shank of the holder. As the broach is fed into the workpiece, this slight offset creates a wobbling or shearing effect that cuts one small section of the desired shape at a time. On a lathe, the broach rotates in the holder at the same rate as the part; on a mill, the broach stops spinning when it makes contact with the workpiece.

Rotary broaching eliminates the need for a traditional long broach as well as a dedicated broaching machine. "With rotary broaching, you're cutting very precise, complex forms right on your CNC machine," Renner said. This lowers manufacturing costs and also speeds up production.

Since parts don't have to be moved from one machine to another for secondary operations, cycle times are extremely fast. "Being able to produce complex forms like Torx and involute spline serrations in a matter of seconds, at the same time that you're doing all your other operations, is an advantage across all industries," she noted.

On the downside, rotary broaching isn't right for all materials. Over the last 15 years, Renner has seen a "huge" increase in the number of customers who want to use very hard materials. With the rotary broaching process, however, "you don't want to be doing any kind of high-volume production with material that's harder than about 30 A very old process remains a go-to cutting option for many, thanks in part to some key developments. BMS Broaching can produce a wide variety of parts, a small sample of which is shown here. ctemag.com/cteguide.com 31 Rockwell due to things like tool life and pressure," she explained.

For applications involving harder materials, Renner said a newer alternative to rotary broaching can be employed. Known as punch or single- point broaching, this technique relies on a "peck mode" that has the tool making a number of shallow passes to remove material a little at a time until the desired shape and depth have been achieved. With this method, parts made of difficult-to-machine materials can be produced at high volumes on CNC machines.

Renner pointed out that single- point broaching isn't as fast as rotary broaching, but it is a way to use a CNC machine to take on applications that are not appropriate for that process. She noted that single- point broaching is ideal for slotting keyway forms, as well as for producing splines, couplings and other parts with tooth heights that require greater pressure to make than the rotary broaching process allows.

An electromechanically powered broaching machine, the eco-friendly BMS Dual Drive features clean operation and low energy consumption. BMS

Another option that allows broaching on CNC machines is the REV broaching tool, developed by the Italian firm F.P. Officina Mechanica. Attached to a mill or lathe, the company's motorized tools use a reciprocating in-and-out motion to create part features. Like rotary and single-point broaching, REV broaching on a CNC machine eliminates the need to re-fixture parts when they're moved from machine to machine, which increases cutting accuracy, noted Preben Hansen, president of Platinum Tooling Technologies, a distributor in Prospect Heights, Illinois, that sells REV tools. Hansen added that REV tools are not a recent development, but the technology has been refined in the last couple of years to boost both accuracy and production.

On the negative side, he also pointed out that REV broaching is limited when it comes to stroke length, which in turn puts a limit on part sizes. "You're probably looking at no more than 2½" of stroke," he said. "Anything longer than that and you probably have to go back to the more traditional (broaching) methods."

Machines move forward

For those still interested in dedicated broaching machines, developments have been made that make the option more attractive. For one, more broaching machines are being built with electromechanical instead of hydraulic power, according to Matt Egrin, president of Broaching Machine Specialties (BMS), a seller of broaching machines and tools in Novi, Michigan. Driven by ball or roller screws, electromechanical machines eliminate some of the backlash that causes chatter in hydraulic machines, which results in better part finishes, Egrin said.

In addition, systems with screws driven by servo motors are more accurate than hydraulic machines, noted Ken Mackenzie, general manager of Crankshaft Machine Group (CMG) in Jackson, Michigan, another seller of broach tools and machines. Servo-driven systems, he explained, include encoders and linear scales that allow more precise positioning than oldstyle hydraulic cylinders and limit switches — thereby boosting part quality and reducing scrap rates. The servo/screw combination also eliminates the need for a large hydraulic tank, which frees up floor space, he added.

The lack of hydraulics offers other benefits as well. One is that plants with electromechanical machines don't have to deal with oil leaks on the floor, noted Egrin of BMS. Besides running cleaner, he said, electromechanical systems run quieter and cooler than their hydraulic counterparts. Moreover, they're significantly less power-hungry, which is good for the environment and the corporate bottom line. "With a hydraulic machine, the motor's constantly idling whether or not the machine is in motion," Egrin said. "But with an electromechanically powered machine, the motors are only turned on when the machine is in motion. So you're saving probably at least 30% on the electrical bill."

Egrin also reported that BMS has recently supplemented its machine offerings with vision and measuring systems. Measuring systems provide direct feedback for part inspection, while vision systems help with part loading and orientation, which increases throughput by reducing cycle time. In addition, he pointed out that more broaching operations are now benefiting from robot loading, which eliminates operator error and can also cut cycle times and part costs.

Motorized REV broaching tools create part features with a reciprocating in-and-out motion. Platinum Tooling

In some applications, noted CMG's Mackenzie, linear rails are used to load parts, as well as to present the fixture to the broach tool and move the tool during cutting. While linear rails allow higher speeds than conventional cast slides and hardened box ways, they have shorter lifespans due to the vibration generated during broaching. "Linear rails are great in some cases, but they don't like vibration — and broaching tends to cause a lot of vibration," he said. "That's why a lot of machine manufacturers will stick to the hardened ways and cast-iron slides."

Mackenzie added that the lifespans of roller screws in broaching applications are also shorter for the same reason. While hydraulic systems and cylinders can fail, he pointed out that broach machines can still operate with a hydraulic leak. Failures in roller screws and linear rails, however, can cause overloads of servo motors, he said.

When it comes to trends in the broaching business, Mackenzie reported a significant increase in the demand for rebuilt machines, both hydraulic and electromechanical. In most cases, he explained, the carcass of an old broach machine is reusable and can be refit with new and rebuilt parts. The appeal of this option is that a rebuilt machine is usually about 40% less expensive than a new one, he said.

Tools today

As for broach tools, important developments cited by Mackenzie include the practice of making them using CNC lathes and mills, which produce more precise and uniform tools than manual machines. "CNC grinders can hold microns, which will improve part quality," he said.

Mackenzie also pointed to advancements in tool coatings, with TiN, TiCN, TiAlN and AlCrN now frequently used by broach tool manufacturers. He noted that these coatings increase tool life and surface hardness in cutting areas, while also providing a little lubricity to produce smoother cuts and better surface finishes.

Another development is the response of broach tool makers to increased demand for specially designed tools. "We're seeing a lot more requests for custom products," reported Renner of Slater Tools. Instead of sticking with standard serrations or splines as was common practice in the past, for example, she noted that many manufacturers now want tools that allow them to produce individualized versions of these features in order to set their products apart from competitive offerings. In addition, "we're seeing a lot of people pushing the boundaries of how deep (a feature) needs to be or where it's located on the part," she said. "So a lot more engineering goes into each product we're selling."

In some cases, she added, custom- designed broach tools also make it possible for manufacturers to eliminate EDM from their processes, allowing them to go into production with just a lathe or mill. "Oftentimes, we are able to come up with a solution, whether it is rotary or punch broaching, that will greatly reduce their cycle times and costs," she said.

Not only do many of Slater's customers want custom broach tools, they want them fast. "We often see people who need something basically the next day," she noted. "Over the years, we've automated a lot of our processes so that we're able to provide really quick turnaround." Today, she said, Slater can deliver a specially designed hex- or square-shaped broach tool the next day, while delivery of more complex profiles typically takes about five to seven days.

Slater punch broaches efficiently cut single and multiple keyways into braking and steering components for electric vehicles. Slater Tools

Typical uses

At CMG, the bulk of the broaching business has always come from manufacturers of internal splines, keyways, transmission components and hydraulic pump parts. Recently, Mackenzie has also noticed an uptick in business from arms manufacturers that make AR15 parts. Instead of requiring multiple setups on a CNC mill, he noted that the hand guards and upper and lower receivers on these weapons have features that can be broached in one cycle on a broach machine.

According to Hansen, Platinum Tooling's REV broaching tools are used mainly to put keyways in aerospace connectors. Another common application is creating precisely made teeth shapes for gears and splines. "Probably the biggest challenges have been with teeth profiles, which are difficult to achieve in some cases," he said. "A lot of components that have internal or external teeth can be done with broaching."

Though broaching is long in the tooth, it looks like there's plenty of life left in it from where Hansen sits. Recently, "our broaching business has grown every year," he noted. "And every week we're involved in a new broaching project."