Advanced Machining Fuels Growth

Advanced Machining Fuels Growth

Sugar River Machine's "2.0" strategy—facility expansion, Mazak multitasking tech, and diversified customers—is driving rapid growth and new opportunities.

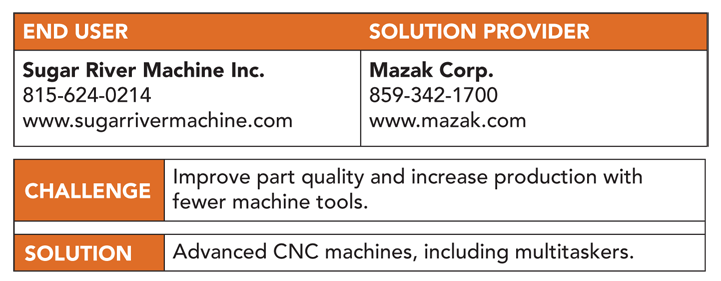

Sugar River Machine Inc. in South Beloit, Illinois, is one contract manufacturer that is reaping the rewards of strategic investment and sustained growth. As part of the shop's strategic growth plan, President and Owner Eric Neilson and his team have not only expanded the shop's production floor-space but also its advanced machining capacity, all of which has led to a significant influx of new work from its current 140-plus customer base.

Neilson took ownership of the shop in 2020. At the time, he had zero machining background, but, thanks to relatives who did have that background, he was familiar with the industry. He believed his previous corporate experience would be a good launching pad for acquiring a contract manufacturing shop.

With that goal in mind, he began an extensive search for a shop to acquire. Neilson evaluated over 55 potential shops, then met Sugar River Machine owners Dave and Diane Klingmeyer. They were ready to retire and had no immediate family members interested in taking over the reins. The Klingmeyers said they were not only thrilled Neilson wanted the garage-born shop, they were confident he could grow it further.

"They didn't just sell me a business," Neilson said. "In a manner of speaking, they sold me their family of team members, many of whom are still working at the shop today. Our customers often ask me, 'Why a machine shop?' My response is that I have a good team on the ground that can produce quality parts. We all work 'on' the business — selling it and attracting new customers — not 'in' the business."

He refers to the shop's business growth strategy for continued success as "Sugar River Machine 2.0." Besides doubling the shop's production floor space from 650 to 1,300 sq. m (7,000 to 14,000 sq. ft.), the plan involves bolstering the shop's machining capacity and capabilities.

"We want to be a full-service, one-stop shop for our customers," Neilson said. "We currently offer turning, milling, grinding, plating, black oxidizing, chroming and anodizing, as well as handle all the other aspects of part production. We're much more than just a machine shop. We're a contract manufacturer, and besides producing piece parts, we provide other services such as welding, painting and assembly to our customers."

After expanding its facility, the shop added more CNC machines, all of which were from Mazak. The equipment allows Sugar River Machine to better serve its customers with advanced machining capabilities, such as multitasking machines capable of performing turning and milling in a single setup, while improving part quality and, most importantly, increasing production with fewer machines, he noted.

"For us, the multitasking machines are two for one," Neilson said. "If we didn't have them, we would have to do part turning on one machine and milling on another. That would also mean two operators and longer lead times."

In addition to a couple of existing older Mazaks still in use at Sugar River Machine, the shop added two QT-Ez Mazak multitasking machines that have milling and Y-axis off-centerline capability, along with four Mazak VC-Ez 20 vertical machining centers (VMCs) and one Mazak VC-Ez 26 VMC. The QT-Ez 8MY was the shop's first foray into multitasking and a key factor in Neilson's Sugar River Machine 2.0 plan.

"If we aren't investing in advanced machine technology like multitasking, another shop down the street with it would beat us out and win the work," he said. "We weren't sure how much we'd use the machine, but it worked out so well that we acquired the second Mazak multitasking machine."

At first, the shop was able to transfer about 20% of its current work to the new machines, but, most importantly, it was able to use the other 80% capacity and the machines' capabilities to win work the shop wouldn't have other wise won with their single-process equipment. The machines have also slashed setup and cycle times, Neilson noted. On some jobs, both have dropped by as much as 60%.

When it came to the VMCs, Neilson admitted that Sugar River Machine did look at other brands of machines besides Mazak. However, he realized that equipment standardization would benefit the shop.

"We asked ourselves do we want to bring in another machine brand, or do we stick with the same because we're familiar with them," he explained. "We stuck with what we know, which were Mazaks. For us, sticking with the same brand means the machines use many of the same replacement parts and operate the same. Once trained, our machinists can quickly move between Mazaks, programming and running each with ease."

Lucas Goza, lead turning machinist at the shop, attests to the ease of use and intuitiveness of the Mazak machines. According to him, once a machinist can program a Mazak, it's easy for them to make the transition from one Mazak to another. Goza does all his programming at the machine and said the Mazak Mazatrol SmoothEz controls make doing it fast and easy.

In terms of parts, the high-mix/ low-volume shop's biggest challenge is that it does such a wide array of jobs on its multitasking machines, Goza said. One day he'll run parts 3.175 mm (0.125") in diameter and the next day parts that are 152.4 mm (6") in diameter.

"Sometimes one part requires 12 hours of work because of numerous critical features," Goza said. "Then the next job is not so complex with more open tolerances and must be completed as soon as possible. Every day is different, and the Mazaks allow us to adapt and balance our varying jobs."

The shop's job lot sizes range from an average of five parts to as many as 400. Part materials include all the basic aluminums, copper, Inconel, Nitronics and plastics.

Another key goal of Neilson's Sugar River Machine 2.0 plan is to further develop the shop as a contract manufacturer with a diverse customer base where no single company makes up more than 20% of the shop's business. While some shops rely on one or two customers for the bulk of their work, Neilson believes that doing so is a risky way to run a business.

"We now have a very diverse customer base and have added new customers," he said. "We're also expanding the number of jobs we handle for our existing customers."