Contact Details

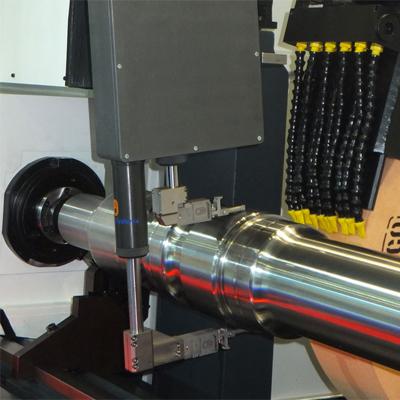

Balance Systems' Top Gauge Absolute (TGA) helps to improve precision and efficiency in manufacturing processes through an accurate measuring of workpiece diameter. It combines a Balance Systems TG200 gauge head with state-of-the-art mechatronic solutions for a quick measuring process and high accuracy. It measures all diameters within its measurement range, with pre/in/post-process cycle, with no need to reset the single diameter.

Features include:

- Two simultaneous measuring processes; availability in combination with the measurement of the axial position (active or passive flagging)

- 32 part programs

- Measuring of smooth and interrupted surfaces

- In-process roundness and shape analysis

- Six commands to control the infeed

- Thermal compensation

- Remote programming

Benefits of the system:

- Allows productions to be stable and consistent and with tight tolerances

- Compensates the grinding wheel wear

- Increases productivity

- Can be implemented both on new and existing machines in the field (retrofitting)

- Easy to use

- Does not require surveillance

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

PRODUCTS

PRODUCTS