Contact Details

ISCAR is expanding the PENTACUT Line by adding:

- PENTA 17… miniature precision inserts

- PENTA 24N-C extended width range

- PENTA 27… a wide pentagonal blank to be ground for special profile contour turning

PENTACUT-17

ISCAR is introducing 17 mm diameter PENTA inserts, designed for machining small size parts with up to 4 mm maximum grooving depth capability.

The new inserts are available in a range of widths from 0.25 to 3.18 mm, with different edge configurations for parting, grooving, turning and threading.

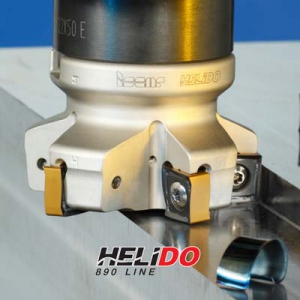

PCHRS/LS-17 Tools carrying inserts with 5 cutting edges for grooving, parting and recessing next to high shoulders.

Features

- For the miniature parts industry

- Precision insert featuring high indexing repeatability precision for 5 cutting edges

- Edge indexing enabled from both tool sides

- Short head design – most suitable for small machine tools

- Very rigid and accurate clamping

Insert Types

Note: All following inserts can be used for next to high shoulder applications.

PENTA 17-P-RS/LS

Precision grooving and parting pentagonal inserts with a positive rake inclination and sharp cutting edge. Low cutting forces, reduced built-up edge. Used on soft materials, thin parts and general parting at low feed.

- P

PENTA 17-MT-RS/LS 60°

Partial profile, external threading pentagonal inserts for general industry.

- MT

PENTA 17-NP-RS/LS

Precision grooving and turning pentagonal inserts, used on Swiss type automatics and small CNC lathes.

- NP

PENTA 17-WT-RS/LS 55°

Partial profile, external threading pentagonal inserts for general industry.

- WT

PENTA 17-ER/EL

Back turning pentagonal inserts with a flat top rake for short chipping materials, used on Swiss type automatics and small CNC lathes.

- ER/EL

PENTA 17-New Packaging

PENTA 17 inserts are available in a new 10-piece packaging box that can be split into two compartments, so that customers can order 5 inserts at a time.

10 Inserts Option

5 Inserts Option

PENTACUT-27

ISCAR is introducing the PENTAS 27-20FT blank insert made from grade IC08. It is a 27mmdiameter pentagonal blank insert designed for the production of special profile contours.

The PENTAS 27-20FT blank insert features 5 cutting edges that can be ground according to enduser specifications for up to 20 mm profile width.

ISCAR offers standard PCHR/L-27-JHP tools in 20 and 25 mm shank sizes. The tools feature rigid clamping and channels for efficient high-pressure (up to 340 bar) edge cooling.

Specially tailored tools can be provided on request.

The new PENTACUT-27 system provides an economical solution for wide profile plunge turning, as it offers a five-edged insert compared to the single-edged inserts that are commonly used.

Designed to be used on popular dovetail adaptation holders on multi-spindle machine tools.

ISCAR is expanding the PENTA 24N-C by adding inserts in 4.78, 4.86 and 5.00 mm widths.

PCHRS/LS-17

Tools Carrying Inserts with 5 Cutting Edges for Grooving, Parting and Recessing Next to High Shoulders

Related Glossary Terms

- built-up edge ( BUE)

built-up edge ( BUE)

1. Permanently damaging a metal by heating to cause either incipient melting or intergranular oxidation. 2. In grinding, getting the workpiece hot enough to cause discoloration or to change the microstructure by tempering or hardening.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- plunge turning

plunge turning

Form of hard turning that uses the entire cutting edge or a portion of the cutting edge to create an orthogonal cut.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- recessing

recessing

A turning operation in which a groove is produced on the periphery or inside a hole of a workpiece. The grooving tool moves at right angles to the axis of rotation.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.