Contact Details

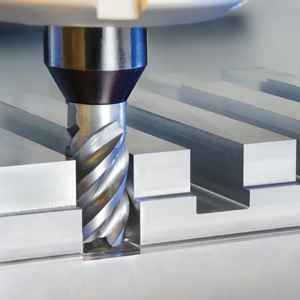

ISCAR introduces new indexable milling cutters for 90° square shoulder and face milling applications which mount square inserts with 8 cutting edges.

This new family of tools was designed for rough and semi-finishing operations, intended for highly efficient face milling applications, primarily for steel and cast-iron.

The HELIDO S890 tool line offers a versatile and cost-effective tool for productive milling for varying cutting conditions.

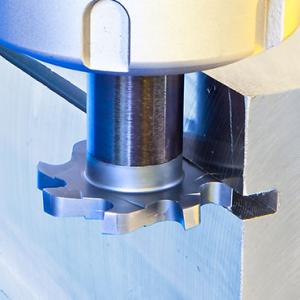

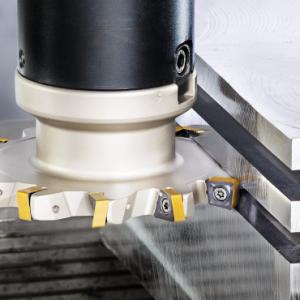

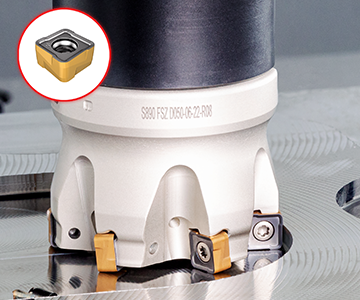

The new HELIDO S890 FSZ …R08 face mills feature a 90° cutting edge angle and mount square double-sided inserts (S890 SZMU 08) with 8 cutting edges. The new cutters have a face mill design configuration and are available in a diameter range of 40-125 mm.

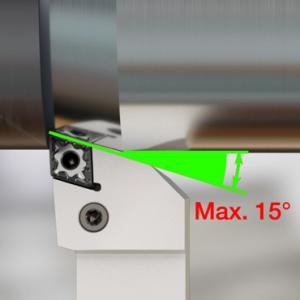

The advanced design combines a strong insert structure, a durable cutter body, secure mounting, and advanced carbide grades. This innovative solution enables face and square shoulder milling, while providing an additional option for milling close to shoulders where there are workpiece or work holding fixture constraints.

S890 SZMU 08… insert features:

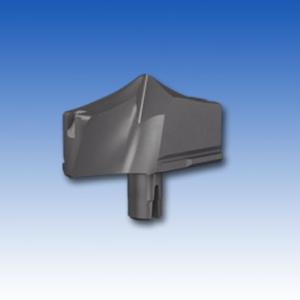

- Square double-sided pressed-to-size inserts

- 8 helical right-hand cutting edges for machining at depths of cut (D.O.C.) up to 5 mm

- Specially shaped rake face insert which ensures a positive rake and low cutting forces

- Strong and durable insert structure

- Wide wiper flat for improving surface finish

- An effective and economical solution for face and square shoulder milling

The inserts are produced from superior SUMO-TEC carbide grades, which provide excellent performance and longer tool life.

S890 FSZ…R08 milling cutter features:

- 90° cutting edge angle

- Maximum 5 mm depth of cut (D.O.C.)

- Extremely rigid screw clamped inserts due to the dovetail profile of the insert pocket

- Advanced cutting geometry which reduces cutting forces and assures smooth cutting and low power consumption

- Coarse and fine pitch configurations of the cutters

- Higher tooth density for improved productivity

- Coolant holes (up to 125 mm Dia. cutters), directed to each cutting edge for efficient cooling and chip evacuation

- A highly economical solution which provides an optimal price per cutting edge

- Excellent performance for diverse machining conditions and interrupted cuts

Machined materials

- ISO P (steel, ferritic and martensitic stainless steel)

- ISO K (cast iron) application groups

Advantages

- Productivity: High metal removal rates

- Economical: Inserts with 8 helical cutting edges

- Reliable: High process machining stability

The new family offers technical advantages combined with a very attractive price per cutting edge. HELIDO S890 FSZ …R08 cutters provide highly productivity solutions for face milling.

Cutting data

- The table below defines initial feed rates

- For initial cutting speeds refer to ISCAR’s recommendations for carbide grades

- For machining under unstable conditions, the table value of the initial feed should be reduced by 20-30%

NEODO

The right tool for high productivity and cost reduction in Square shoulder and face milling

S890 FSZ-R08

Face Mills Carrying Double-Sided Square Inserts with 8 Cutting Edge

S890 SZMU-0804PN

Square Double-Sided Inserts with 8 Cutting Edges

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.