Contact Details

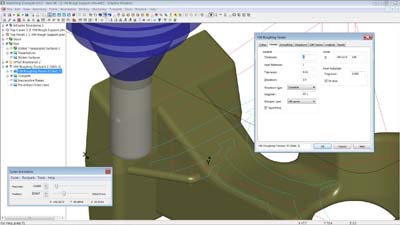

Vero Software has released Machining STRATEGIST V14, a multi-axis CAM solution that generates optimal High Speed CNC toolpaths for both the office and shop-floor environment. Machining STRATEGIST is a CAD independent solution and can work with data from all major 3D modelling systems. Within the latest release, support for VISI 20 has been added and the CAD interfaces have been aligned to Parasolid v25.

Significant product enhancements include a new innovative Roughing algorithm that will greatly benefit both Machining STRATEGIST customers and OEM partners. The new roughing strategy massively reduces rapid moments by controlling the tool movement so that it remains on the part, following previous cut paths instead of rapid feeding to the new position. Additional toolpath optimisation features include the ability to automatically machine flat areas only instead of adding extra Z levels to clean up planar zones.

The new roughing algorithm also permits to the use of a large step over (greater than 50 percent), where an innovative offset algorithm ensures total coverage of the machining area by adding smooth transition corner pips to clean up any remaining areas.

Other significant developments include:

Improvements to linking core area clearance toolpaths.

Linking horizontal area passes from outside to in (core linking). Use pre-drilled entry points for cavity regions of core roughing toolpaths.

Minimise retract moves on vertical walls.

More consistent lead arcs when linking.

Steve Youngs, MS Development Manager concludes "The ever increasing complexity of our customers work continues to drive forward the development of Machining STRATEGIST. Our ability to deliver solutions to their demanding requirements helps us all to win new business. Machining STRATEGIST v14 keeps us at the leading edge of CAM technology as we look forward."

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.